CW-Air-TH

Reliable monitoring you can trust

The CW Air TH sensor combines precision sensing, long-life power, and LoRaWAN connectivity to keep cold storage, hospitality, and industrial sites informed in real time.

Deploy the sensor as part of CropWatch Command for proactive alerts, compliance documentation, and predictable operations across every facility.

Designed for demanding operators

- Validated for HACCP, FDA, and ISO-compliant programs.

- Ships pre-provisioned for CropWatch® gateways to eliminate manual setup.

- Access predictive analytics and alerting through CropWatch® Command.

Key capabilities

Reliable Cold-Chain Monitoring You Can Trust

Our cold-chain sensor stands apart through rigorous testing in some of the harshest real-world environments. Every design decision is driven by reliability — from preventing sensor and device failures to ensuring data integrity under extreme conditions.

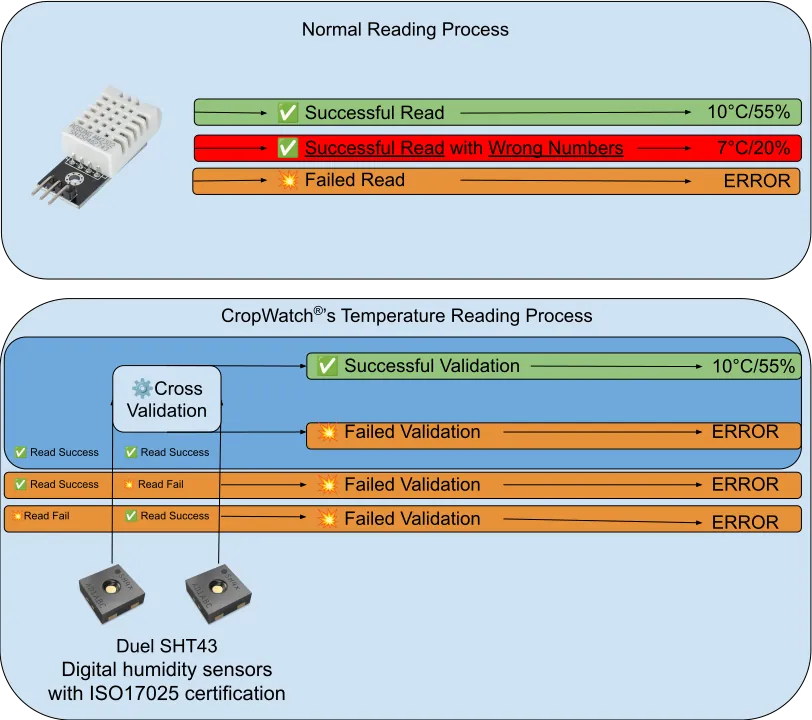

Unlike conventional devices, our system features an intelligent cross-validation mechanism that continuously verifies sensor accuracy and detects anomalies before they become problems. In other words, it answers the critical question: "What happens if a sensor stops reporting the correct value?"

At CropWatch, our goal is simple: deliver the most reliable and accurate cold-chain data in the industry — so you can make confident decisions, backed by data you can trust.

Cross-validated, Fail-Stop system for safe operation

The CW-Air-TH continuously cross-checks its replaceable sensor against each other to confirm every value before it reaches your dashboards. If the primary probe drifts or reports outside expected tolerances, the device flags the anomaly instantly and notifies you of an issue.

- Dual-channel comparison cross-validates live telemetry against each other.

- Automatic Fail-Stop prevents bad data from ever reaching your dashboards.

- Exception events sync directly into compliance logs so auditors see proof of every validation step.

Rugged industrial enclosure

IP67-rated shell with conformal coated electronics keeps the sensor operating in freezers, loading docks, and production floors.

Precision monitoring

High-accuracy digital sensing provides +/- 0.2°C temperature and +/- 2% RH readings for compliance-ready reporting.

Multi-year battery life

Engineered for more than 10 years of continuous telemetry with field-replaceable lithium batteries and low-power firmware.

LoRaWAN connectivity

Secure LoRaWAN connectivity ensures resilient transmission through dense infrastructure and cold storage insulation.

Technical specifications

Engineered for reliability

| Sensor | Sensirion x1 SHT40 & x1 SHT43, True NIST, w/ISO17025 Certification |

|---|---|

| Temperature range | -40°C to 85°C (calibrated) |

| Humidity range | 0% to 100% RH (non-condensing) |

| Integrated Heater | Ensure condensation prevention in cold environments |

| Temperature accuracy | +/- 0.2°C between -10°C and 50°C |

| Humidity accuracy | +/- 2% RH between 10% and 90% |

| Ingress protection | IP67 enclosure |

| Wireless protocol | LoRaWAN 1.0.4 Class A, regional bands supported |

| Battery | Li-SOCl2 (lithium thionyl chloride), field replaceable |

| Dimensions | 120 mm x 70 mm x 35 mm |

| Operating life | Up to 5 years at 15 minute intervals |

| Certifications | FCC, CE, IC, HACCP compliant materials |

Deployment kit

Everything you need to go live in days

Every CW Air TH sensor arrives fully configured and ready to join CropWatch® Command, with mounting options and documentation tailored to regulated environments.

- CW Air TH sensor with pre-configured firmware

- LoRaWAN activation credentials and QR deployment tag

- Stainless steel mounting bracket with hardware and adhesive pads

- Calibration certificate and validation documentation

- Install and cold storage handling playbook

How we deploy

Proven rollout workflow

Our hybrid deployment model keeps install timelines short while ensuring every stakeholder has the training, telemetry, and reporting they need to succeed.

Site planning

CropWatch specialists map facility zones, determine gateway placement, and align telemetry intervals with compliance needs.

Rapid install

Technicians mount sensors using magnetic, adhesive, or bracket hardware options without disrupting production.

Automated validation

Sensors perform baseline calibration checks and register with CropWatch Command for continuous monitoring.

Insight delivery

Real-time dashboards, alerts, and audit-ready reports empower teams to resolve anomalies before they escalate.

Designed in Norway

Manufactured & Assembled in Japan

Using Parts from:

Japan, South Korea, USA, Taiwan, Ireland, and SwitzerlandProgrammed in the USA & Japan

Used by You

Documents

Downloadable files and resources

Explore our collection of documents, brochures, and technical specifications to learn more about CW-Air-TH and its capabilities.

Example Report

An example report that would be generated by the CropWatch User Interface's Report feature

Download Sample ReportCSV Data Export

A CSV data export sample from the CropWatch User Interface containing temperature and humidity readings.

Download Sample DataSee CW Air TH in action

Schedule a walkthrough or start a pilot

Connect with CropWatch® specialists to map out sensor placement, gateways, and analytics that keep your environments compliant and efficient.